YUP. The storefront is now dead and gone at i.materialise. Thursday, May 29th, 2025.

😭☹️

Hi folks

If you want to buy a BD silent damper cap for your modern or vintage stove. Now is the time. You have a deadline of 28/5/2025 (May 28th, 2025) to place that order.

https://i.materialise.com/en/shop/designer/gary-adams

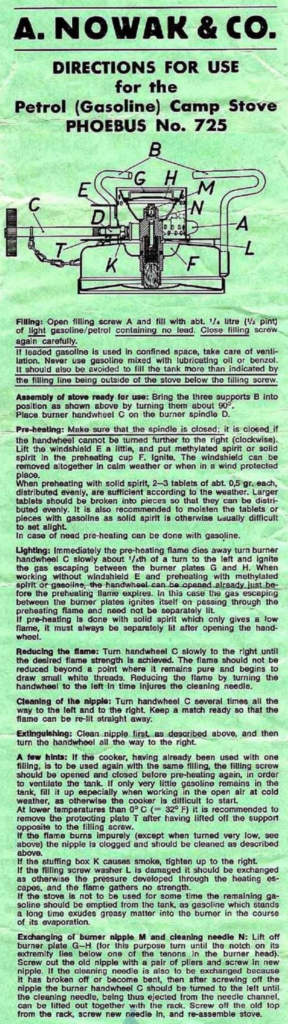

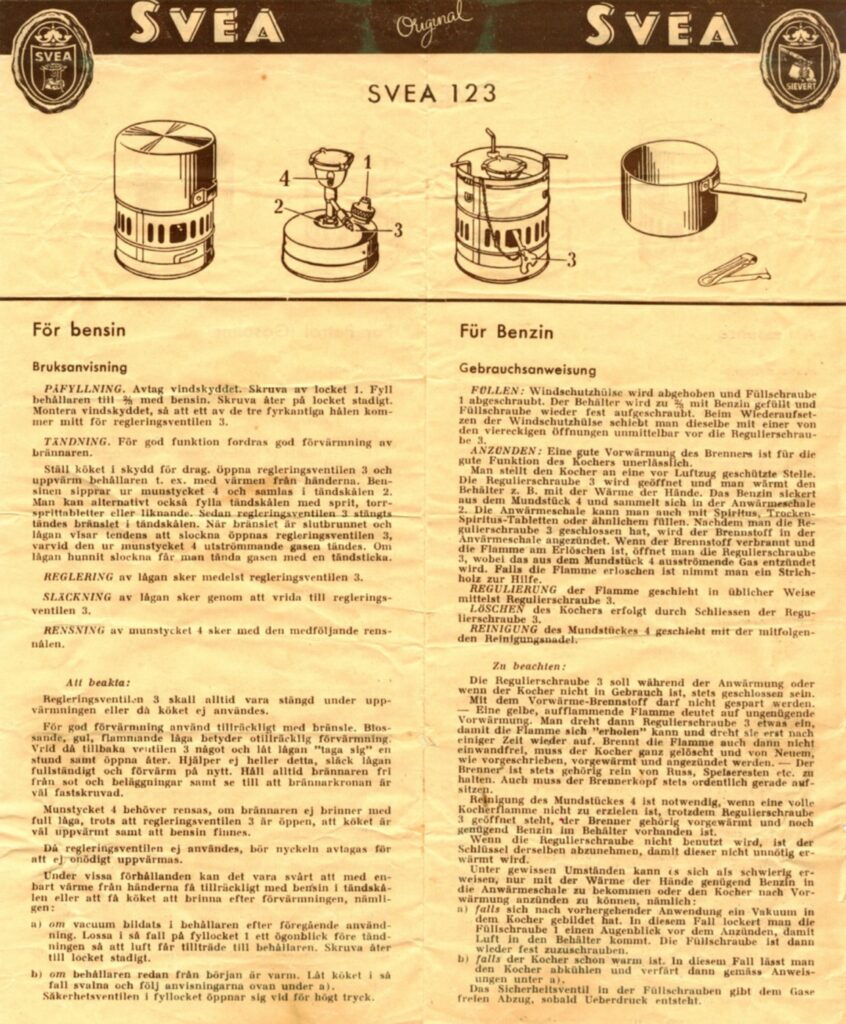

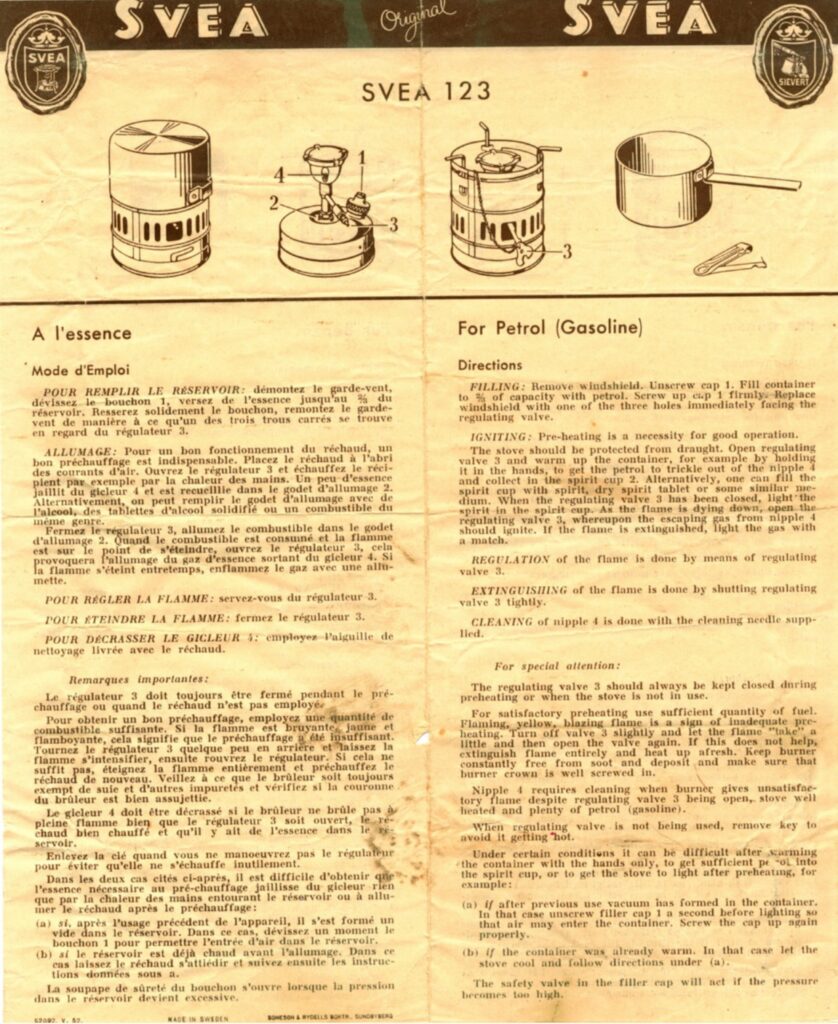

Cap instructions: https://www.berniedawg.com/berniedawg-silent-damper-cap-instructions/

Here is why.

I received this email on 16/5/2025:

Will there be more caps sometime in the future from some other outlet? Maybe or maybe not. I ain’t getting any younger and the logistics of setting up another source are daunting. So! If you want one, NOW is the time to act. Sorry this is this way. Dumb that I get less than two weeks notice and have to pass that on to you. Out of my control however. Still, I’m so sorry it should be that way.

Link again: https://i.materialise.com/en/shop/designer/gary-adams

BD